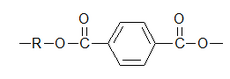

Steinerfilm® T is based on biaxially oriented polyethylene terephthalate - better known as polyester or the abbreviation PET. This film is offered in various metallizing patterns and individual slit widths for highly customised capacitors and applications.

The molecule shown above is the basis for all PET materials. The specific arrangement of the molecules and the length of the chain separate the today’s materials from other PET-material. The specific formulation of these polyesters built a class of its own.

The film making process uses additives – so called nanoparticles of a certain corn size and distribution. These additives generate the surface structure. A certain roughness is necessary to avoid blocking of layers and to support the winding behaviour.

A key performance indicator for film capacitors is the specific capacitance. This ratio deals with the microfarad per volume and scales with one over thickness square. That pursues the target of the thinnest possible gauge.

The range of film thickness is at the threshold for ”technical” films.

Meanwhile the thickest PET for capacitor application is less than 15 µm (= 0.015 mm). Actually the thinnest commercially available gauge for a PET film is 0.7µm = 0.0007 mm!

A gauge of 0.75µm enables capacitors to be produced with 50 µF per cm³.

Typical data for PET-base

| Density ρ | 1,395 | g/cm³ |

| Melting point | > 245°C | |

| Long-term temperature range | -60 - 130°C | |

| Shrinkage in air md | < 2,5% | @ 150°C, 15 min |

| Shrinkage in air td | < 1,5% | @ 150°C, 15 min |

| Field strength in air DC | ≥ 400 V/µm | @ 23°C |

| Field strength in air AC (50 Hz) | ≥ 300 V/µm | @ 23°C |

| Loss factor tan δ | < 0,005 | @ 1 kHz and 23ºC |

| Dielectric constant | 3,2 | @ 1 kHz and 23ºC |

| Tensile strength md | 160 N/mm² | @ 23°C |

| Tensile strength td | 180 N/mm² | @ 23°C |

| Elongation at break md | 50 - 110% | @ 23°C |

| Elongation at break td | 50 - 110% | @ 23°C |

| Modulus of elasticity md | ≥ 4300 N/mm² | @ 23°C |

| Modulus of elasticity td | ≥ 4500 N/mm² | @ 23°C |

| Spec. resistance | ≥ 10↑17 Ω cm | @ 23°C |

| This difference of machine and transverse direction is typical for biaxially orientated plastic films. | ||