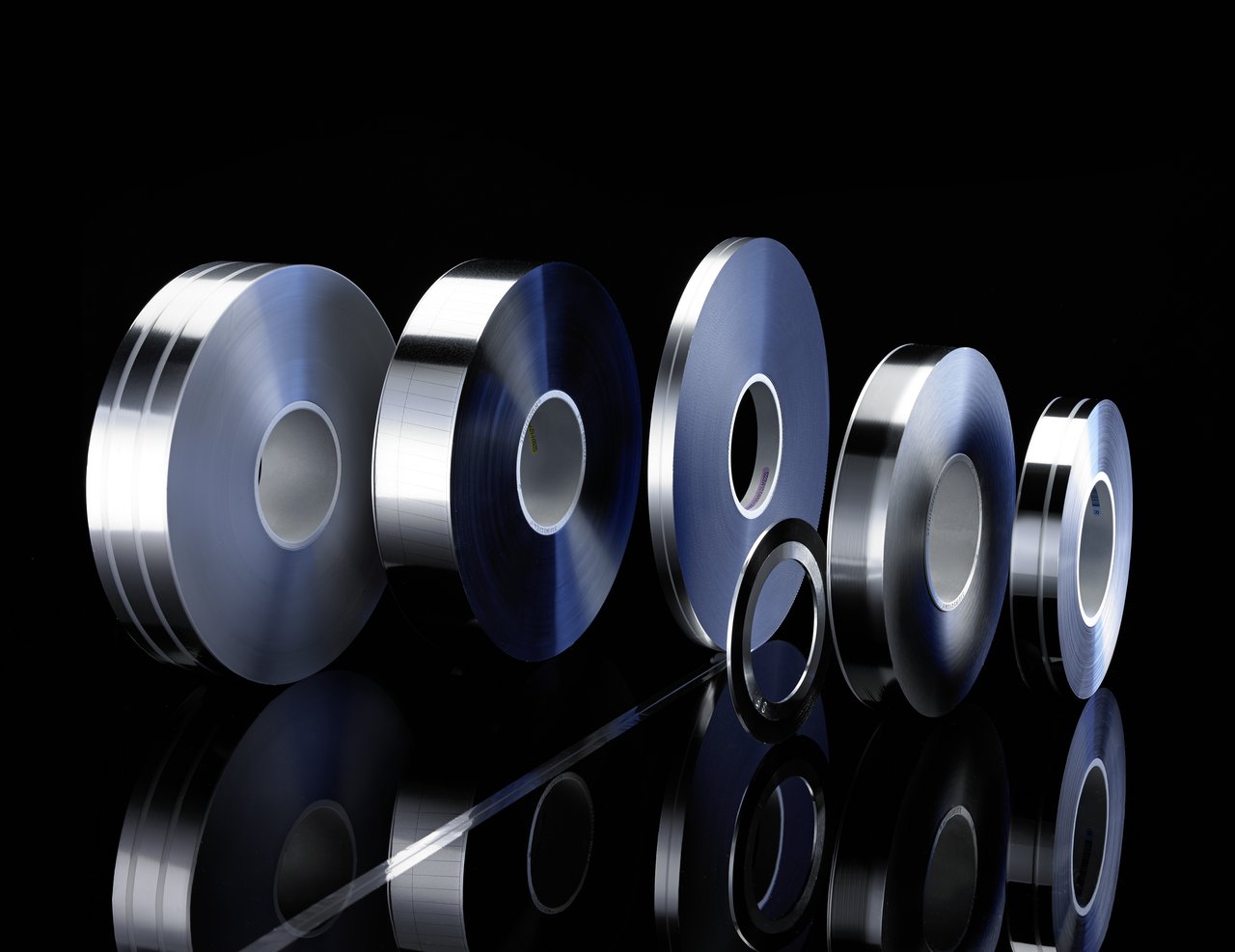

Today´s technology of metallized film capacitors is dominated by the two metals aluminium and zinc.

- Aluminium: Aluminium is particularly suitable for robust designs and high Ohm metallizations due to its brilliant climatic stability. Aluminium layers can, for example, be metallized as low as 200 Ohm/sq. on polypropylene film. Purest aluminium metallizations, including heavy-edge and profile executions, are successful in use for DC capacitors and pulse applications.

- Zinc metallizations are the optimal solution for low frequency AC applications.

Furthermore the metallization process can easily be controlled to achieve sophisticated resistance profiles. As zinc alone does not stick well to plastic films a pre-nucleation of aluminium is necessary. Typically an Aluminium share of 5 % is used. However, any other ratio between Al/Zn can be made to customer's specification. - Silver: also silver is an alternative for the pre-nucleation of zinc metallizations.

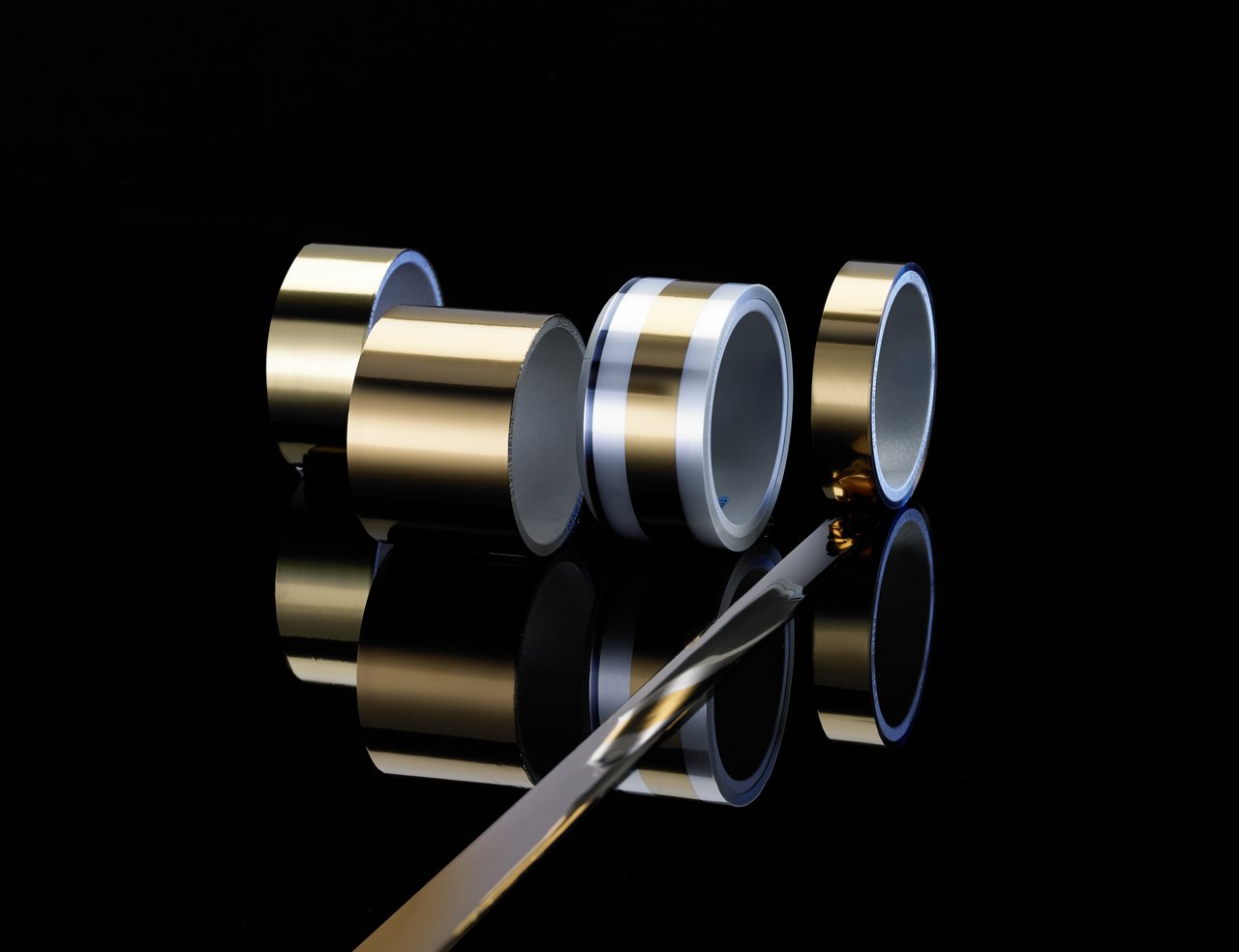

- Gold is used for acoustic membranes and capacitors of high end audio components.

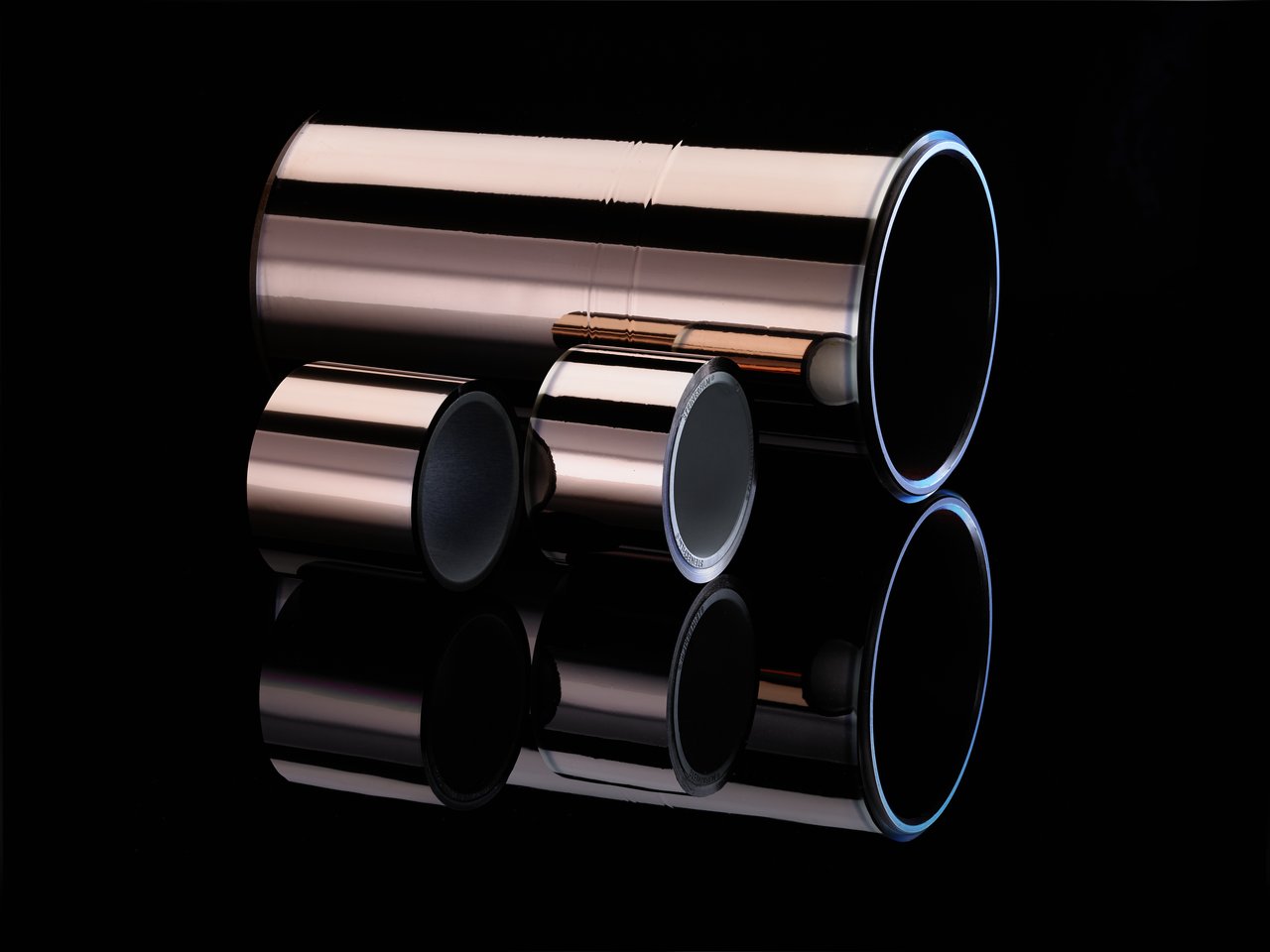

- Copper was successfully tested in capacitors with high frequencies and high currents.

Other materials, e.g. tin, can be metallized with the Steiner technology. This is not valid for capacitor applications only, but also for the use in the fields of decorative films, flexible electronics, chemical/physical membranes etc.