Wave-cut

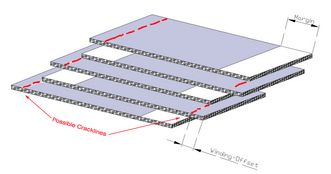

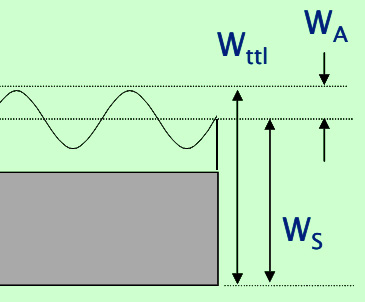

The edge-cut, normally in a straight line, of the capacitor film is done with highest precision in the requested width. For a series of capacitor designs, however, this straight-cut offers disadvantages that can be minimised by Steiner´s wave-cut technology.

1. Inside the capacitor the mechanical contact between the end-spraying layer and the metallized film is an extremely important factor for a good dissipation factor and a high pulse capability. A contact edge in wave-cut form in combination with an optimised winding off-set can significantly improve the contact of the end-spraying layer.

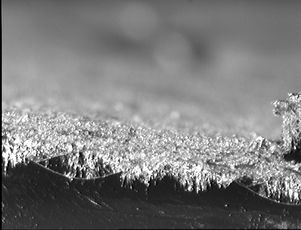

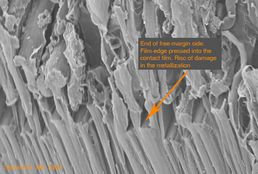

2. Thin polypropylene films wound with a high tension are particularly prone to mechanical stress at the margin side. Damage can then easily occur on the adjacent metal layer. A wave-cut at the free margin edge spreads these stresses and reduces the risk at high operating temperatures or high currents.