Capacitor films where the metallized plane is divided by lines and structures are known as segmented or safety films. These patterns are achieved by an oil masking system during the metallization process.

At Steiner segmented patterns are designed according to the technical requirements of the customer. In practice patterns can be divided into three different basic designs: T-segments, mosaic-segments and cut-off lines. Examples of variations and combinations of these designs are Y, hexagon or brick design.

Remarkable are also “half-segments” where a wide area is fully metallized but the segmented patterns only starts half way towards the free margin edge. See example E) below.

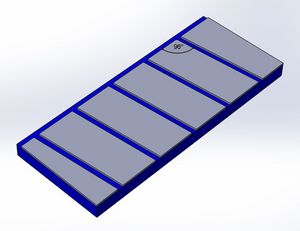

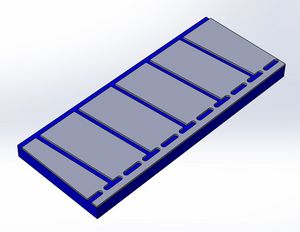

A) Cut-Off lines:

Free lines in transverse direction (TD lines) guide the current from the contact edge to the free margin edge. This avoids the occurrence of circular currents and reduces the parasitic inductance.

In case of a dramatic failure a local disconnection of the end-spray deactivates the faulty area.

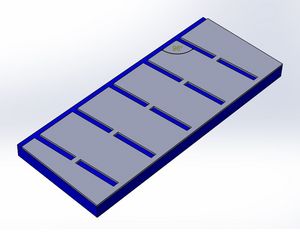

B) TD lines with gaps

The interruption of the TD lines by electrical bridges avoids static charges on separated metallized areas. This static charge often can be noticed in a form of sparks on winding machines.

An interruption in the area of the heavy-edge can furthermore improve the contact to the end-spray layer.

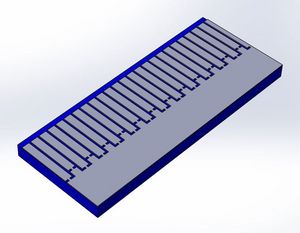

C) T segment:

An essential part of the T segment is the barrier line in machine direction (MD line). The metallized bridges, also known as electrical fuses, are the gate between individual segmented areas and the face side contact. The current flow through the fuses is defined by the size or capacitance of the segmented area behind. An increased current flow results in over-heating and shrinkage of the dielectric material causing a mechanical break of the metal layer. In the event of a dramatic short circuit the appropriate metallized area is isolated and this initial fault will not trigger a disastrous “avalanche effect”.

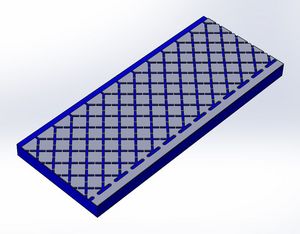

D) Mosaic (Diamond) Pattern

These patterns are characterised by the relatively dense line structure with a high number of fuses. Being quite close to a faulty area the Mosaic pattern reacts fast in case of a failure and deactivates the faulty capacitor area proportional to the intensity of the failure. Mosaic patterns not only improve the safety of the capacitor; correctly fine tuned they will also improve the self-healing mechanism of the dielectric.

E) Special segments

The variety of targets aimed to be achieved by segmentation requires new complex structured patterns. Parameter, such as leakage current, breakdown voltage, loss of capacity, safety function, reduction of inductance have to be duly considered. Even segmented designs to improve the C variation during the capacitor production are available.

We design segmented patterns based on your specification, but we also invite you to develop new, optimised segment designs with us in order to improve your capacitor.